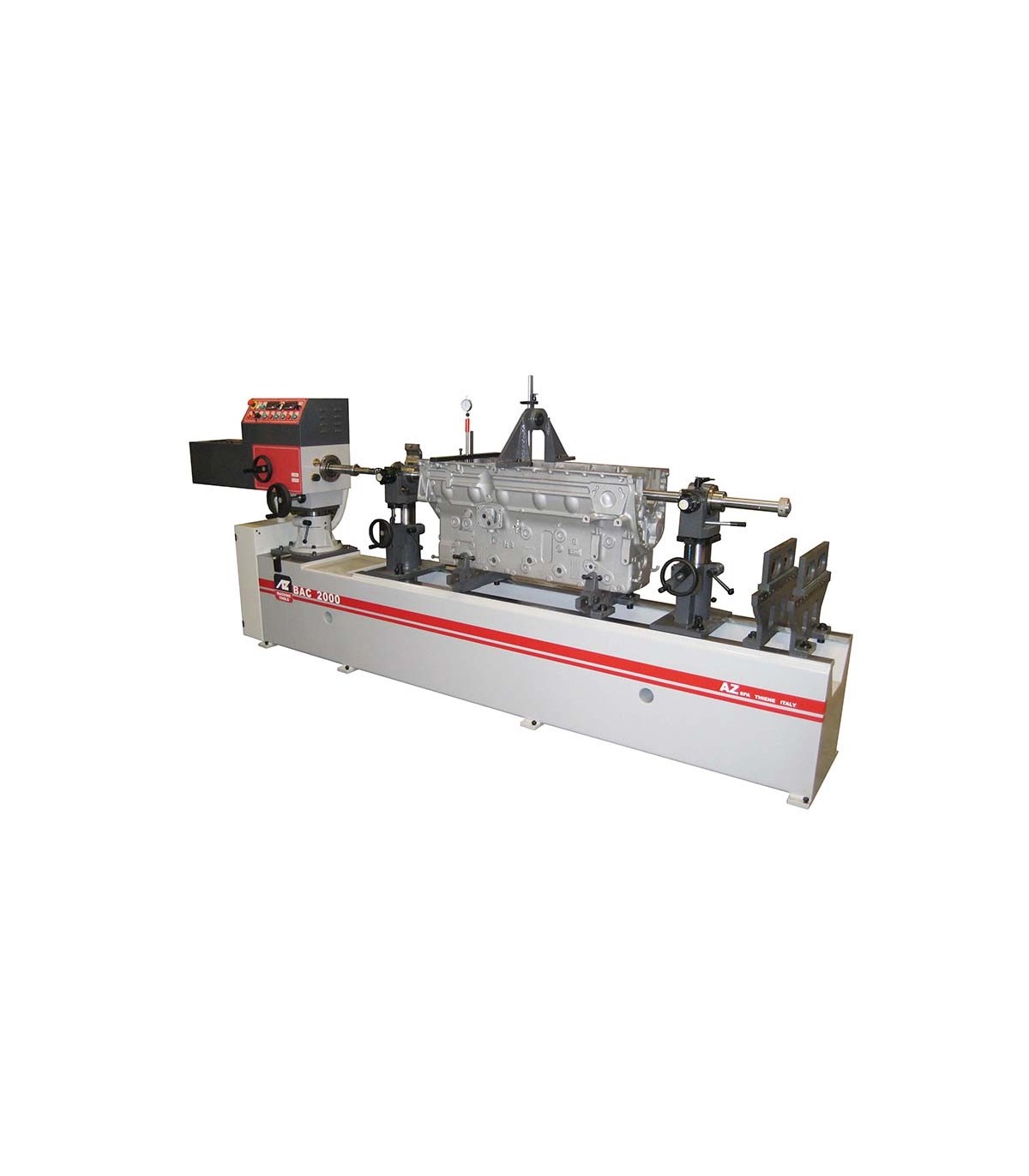

The base is made of electro-welded steel to avoid structural deformations, while the precision machined surfaces and excellent universal fixtures position work pieces securely during operation. The bar rotation is made by belt drive system and pulley with 2HP motor while the feed is driven by gears and variable speed motor. Speed and feed rates have a wide range of adjustments to match the characteristics of engine block material and the size of the bores. The operator can keep close watch on the boring process and can easily make speed adjustments if necessary. A special feature of the BAC series machines is their unusually long spindle travel up to 400 mm (other sizes available upon request) which allows blocks to be bored with fewer interruptions to reposition the tool.

Max length of block : 1500-4200mm

Min e max boring diameter : 23-200 / 23-250mm

Maximum spindle travel : 400+120mm

Min distance from bed to centerline : 450-650mm

Max distance from bed to centerline : 650-850mm

Variable spindle speed : 100-600mm/min

Continuos automatic feed : 0-80mm/min