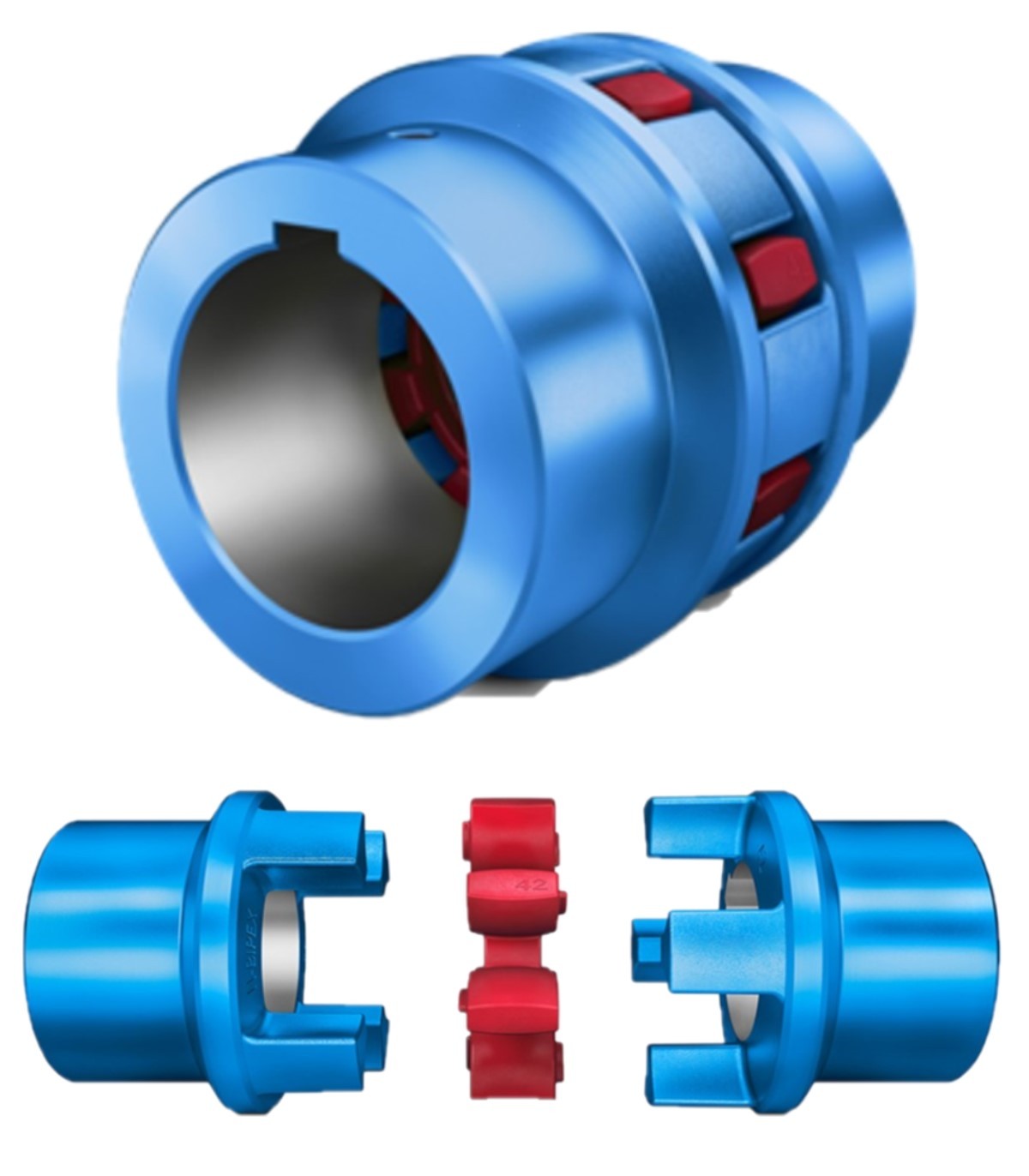

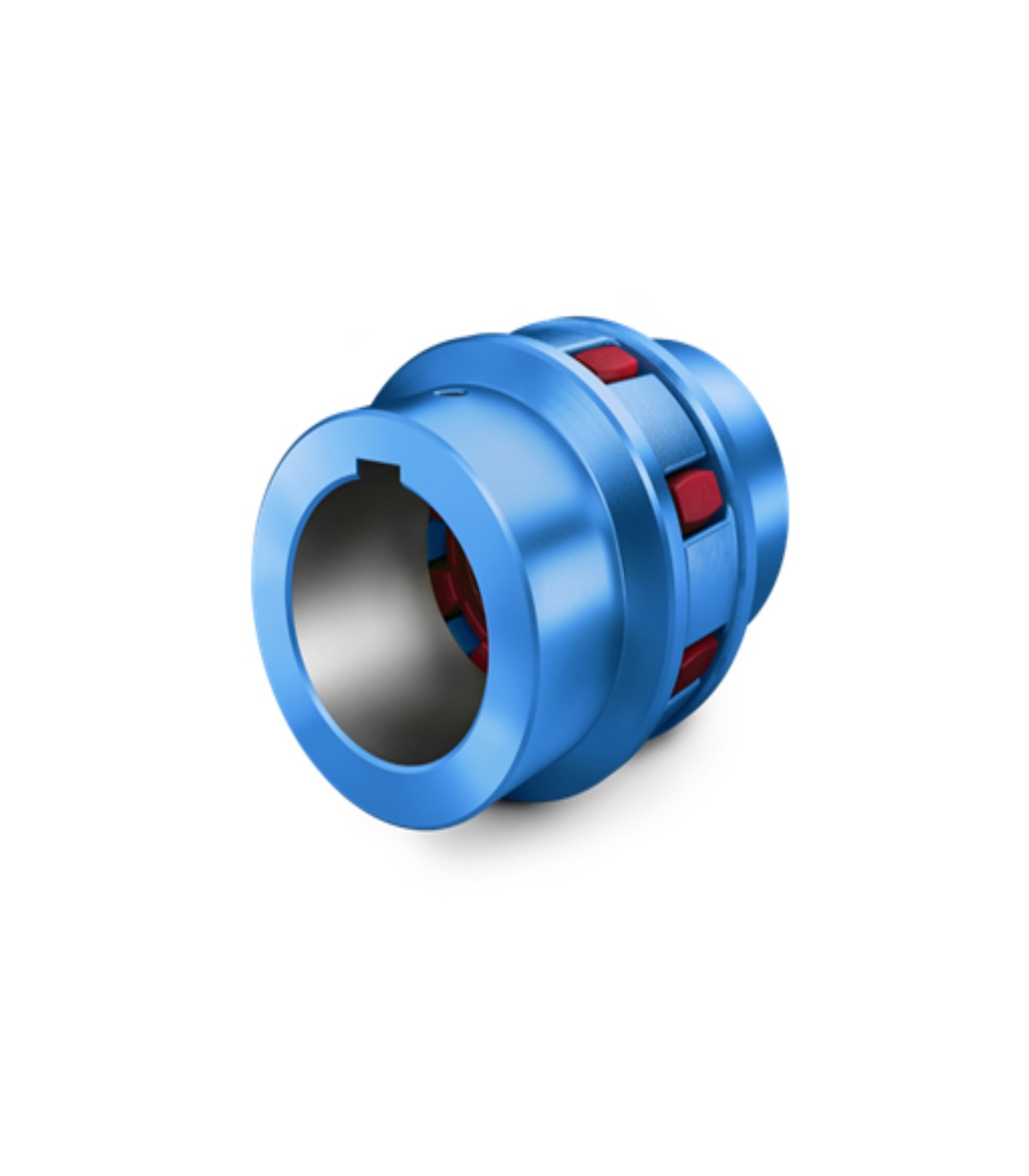

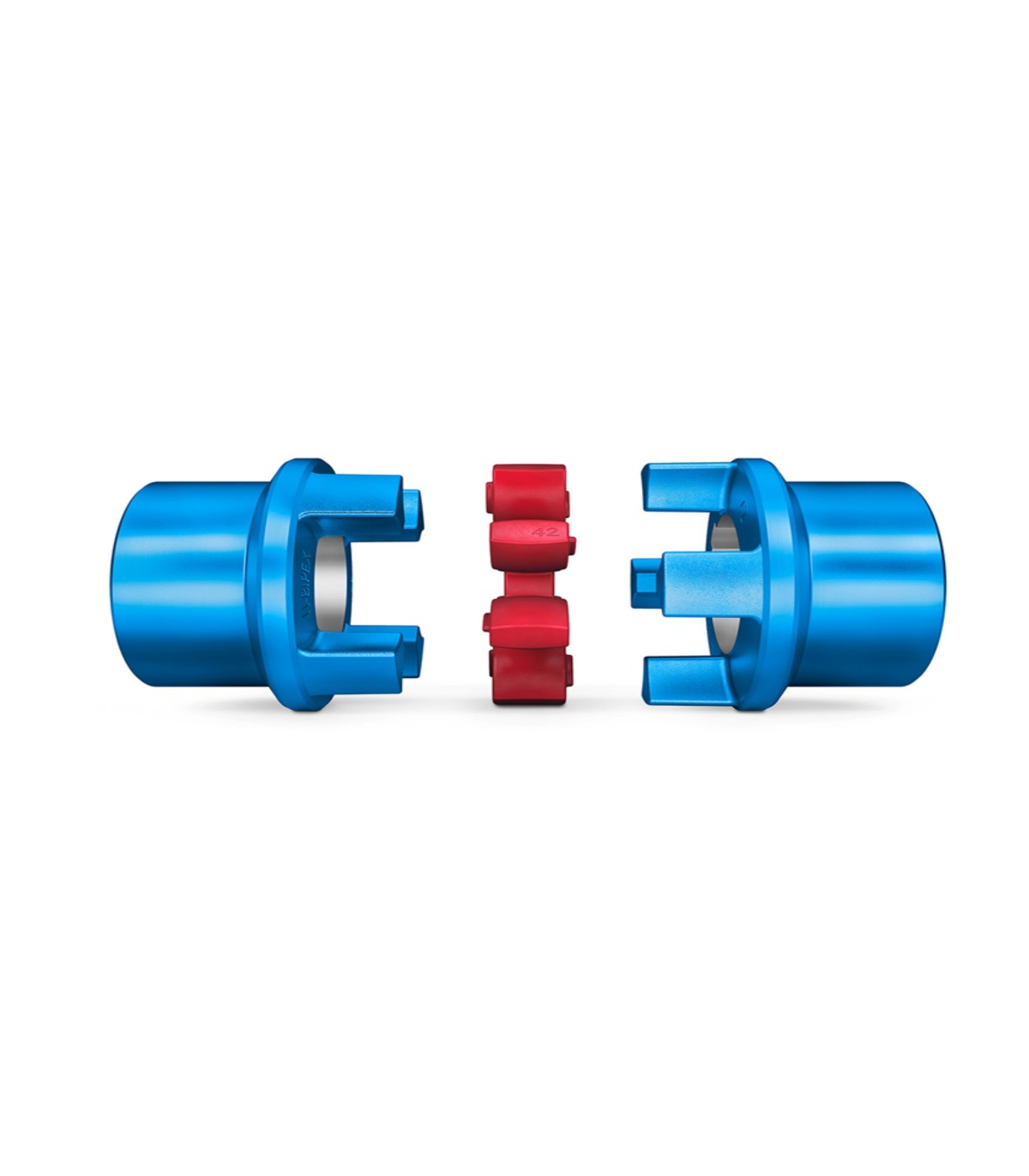

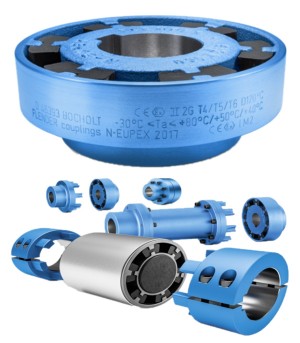

N-BIPEX allows greater freedom when designing the cam geometry, thereby laying the foundation for the innovative curved design. Unlike the milled cams typically available on the market, this design results in uniform loading of the elastomer compression bodies under all conditions and, in particular, prevents inward deformation of the cam ring due to load peaks that can cause greater wear. Hubs made of high-quality nodular cast iron allow the N-BIPEX to cope with high rotational speeds and critical bores. All in all, the N-BIPEX provides reserves that are considerably greater than those normally available on the market, thus achieving a significant reduction in wear.

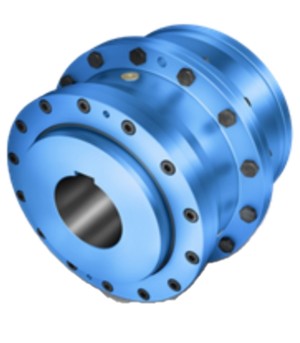

- Damping shaft coupling that can be used universally to compensate for shaft misalignments

- Nominal torque range from TKN = 12 Nm up to 4,650 Nm with 10 sizes

- Temperature range: from – 50 °C to +100 °C

- High torque reserves (maximum torque = 3 × nominal torque) to effortlessly absorb torque peaks

- Reduced complexity and lower storage costs due to the use of a single hub to meet all requirements

- High-quality elastomers that ensure uniform load distribution and thus an optimal service life under all conditions

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)